Gino Plast- cartridged clay plug is a new product on the market with cylindrical shape cased in a plastic foil. Its main ingredient is clay with additives that enable high consistency and adequate density. The clay plug is designed to close (fill-in) the empty space left over after loading the explosive in the borehole especially in the underground mining due to construction of horizontal and inclined underground mining facilities, in the process of excavation but also due to construction of tunnels, shafts, raises etc. which main function is to increase the use of energy generated from the combustion of the explosive.

APPLICATION

After loading the explosive into the boreholes it is essential the unloaded part of the blasthole to be closed with certain object or material which will enable better use of the energy released from the combustion of the explosive.

When suitable product is used for plugging scientifically is proven that the effect of blasting is at least 10-15 % more effective.

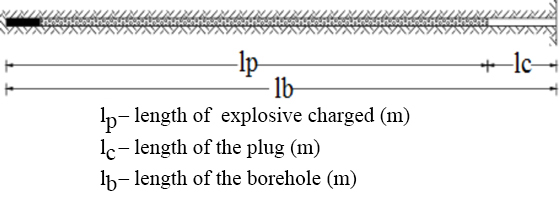

Based on experimental data the length of the plug in the boreholes during the construction of the underground facilities is:

L(p) = 10 x d (m)

Where (d) is diameter of the borehole.

During underground excavation the length of the plug in the blasthole is:

L(p) = (1-1.67) x W

where (W) is a line of lowest resistance.

EFFECTS

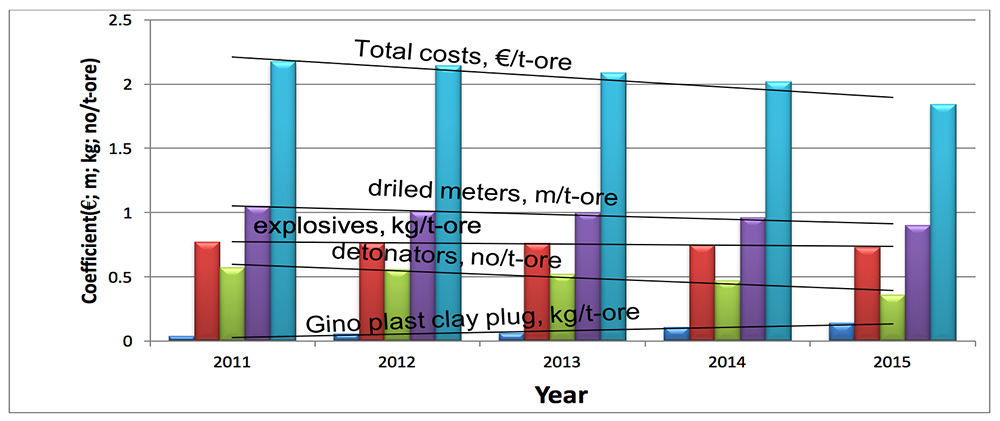

With correct size determination and proper installing of the plugs in the boreholes in the same time one should bear in mind the basic drilling-blasting parameters (drilling geometry, sequence of initiation etc.) allowing higher use of the combustion energy of the explosive and with that the effect of blasting is significantly higher compared with blasting without plugging.

The use of this product influence directly on:

-decrease the costs of materials and equipment’s for drilling and blasting,

- increase of productivity during the carrying out of the main technological operations,

- decreasing of the costs for electrical supply, ventilation etc.

- decrease the construction time of underground facilities.

SAFETY

Although we talking about a product used in blasting any of its components or the product itself is not explosive and therefore is completely safe. On the other hand the product is enclosed in plastic foil which prevents direct contact with the product and its components, even though are entirely harmless and this way allowing the operation be completely safe.

CAPACITY

The improved way of manufacturing of this product during the past years enable on time supply of any order demanded on the current market.

Gino Engineering (DOOEL) possess modern warehouses for storage of the manufactured products but also have its own vehicle for distribution of the orders to the potential buyers.

This way could be guaranteed on time delivery of the requested orders to all of our customers.